About Asbestos Free Brake Lining

Asbestos Free Brake Lining

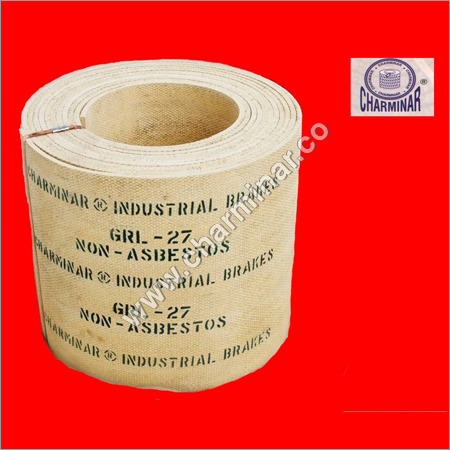

We are one of the leading manufacturers and exporters of Asbestos Free Brake Lining. Manufactured in our advanced manufacturing unit from quality assured raw material with the help of latest machines and ultra-modern technology, the offered lining is widely demanded in automotive industry for drum brakes and disc brakes of transporting vehicles. It is available in different finishes and thicknesses as per the specific requirements of clients. This Asbestos Free Brake Lining is made available for our prestigious clients at market leading price.

Features:

- Low heat conductivity

- Smooth texture

- Minimum lining wear

- Optimum strength

ITEM: GRL 27. Semi-Flexible industrial woven brake linings manufactured from NAM Yarn reinforced with Bras Wire both side grinded.

APPLICATION: Shipping industries winches, cranes, earth moving and agricultural equipment, forging machinery etc.

TEMPERATURE: Max Temp: 230oC

Max continuous temp: 150oC

Co-efficient of Friction: 0.3/0.40

Specific gravity: 1.6 / 1.8

Ultimate compressive strength: 900kg/cm2

Size: Thickness - 5mm to 25mm

Width - up to 510 mm

Length - 15 mtrs/roll (slitting sizes available as per customer's req.)

Customizable Brake Linings for Versatile NeedsWe cater to varying vehicle specifications by offering brake linings with customized sizes and mounting options. Whether you require riveted or bonded installations for automotive, commercial, or industrial machinery, our products are engineered to deliver seamless compatibility and high performance.

Superior Safety and Silent OperationEngineered from asbestos-free organic composites and finished with resin fiber and steel backing, our brake linings deliver robust safety and low noise operation. The smooth surface and precision grinding process further minimize vibration and ensure reliable, silent braking in any environment.

FAQs of Asbestos Free Brake Lining:

Q: How are the asbestos free brake linings manufactured?

A: The brake linings are crafted using advanced organic composites reinforced with resin fiber and steel backing. Each piece is precision ground to achieve a smooth, durable surface and then assembled onto drum brakes using riveted or bonded mounting methods.

Q: What are the primary benefits of choosing asbestos free brake linings?

A: Opting for asbestos free brake linings ensures safer operation, reduces exposure to harmful substances, and supports environmental sustainability. These linings also provide low noise levels, reliable braking, and extended service life in heavy duty applications.

Q: Where can these brake linings be used?

A: They are suitable for a wide range of vehicles and machinery, including automotive, commercial vehicles, heavy-duty transport, and industrial equipment, where drum brake systems are installed.

Q: When should I consider replacing my brake linings?

A: Its advisable to replace brake linings when you notice decreased braking performance, increased noise, or visible wear. Regular maintenance intervals, especially for commercial and heavy-duty vehicles, help ensure optimal safety and efficiency.

Q: What is the process for customizing brake lining sizes?

A: We work closely with clients to assess their specific size and pattern requirements. After verification, our manufacturing team fabricates brake linings according to the designated dimensions and mounting preferences, fulfilling custom orders efficiently.

Q: How do the noise levels compare to traditional brake linings?

A: Our asbestos free organic composite brake linings are engineered for low or silent operation, thanks to the smooth finish and precision ground surface, offering a quieter alternative to conventional products.