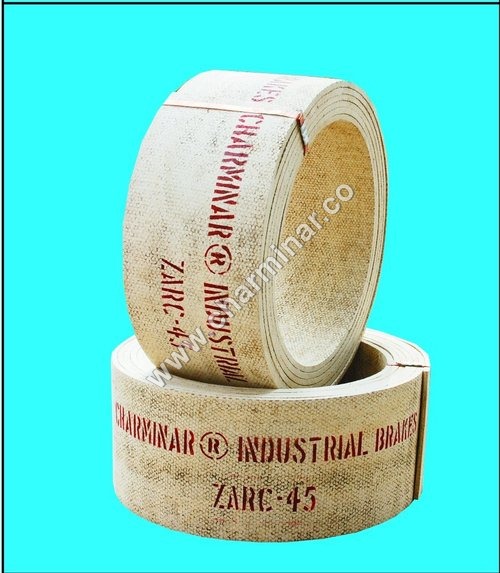

About Asbestos Woven Brake Lining

Pioneer in the industry, we are engaged in offering an impeccable range of Asbestos Woven Brake Lining. Only high quality asbestos material is used while manufacturing the offered brake lining, for increased compliance with international market standards of quality. It is widely used in automotive industry for various applications. Apart from this, our offered Asbestos Woven Brake Lining is offered in different lengths and roll sizes as per precise needs of our clients and at highly competitive prices.

Features:

-

Heat resistance

-

Perfect finish

-

High strength

-

Durability

What Makes Our Asbestos Woven Brake Lining Stand Out?Our brake linings are engineered to perform in rigorous industrial environments, offering high heat resistance and consistent friction. With a textured, woven surface, these linings ensure optimal grip and durability. The product is designed for easy installation and minimal maintenance, providing companies with a flexible solution that adapts seamlessly to a variety of mechanical brake systems.

Versatile Applications and Customization OptionsExtensively utilized in hoists, cranes, elevators, lifts, and conveyors, our brake linings are suitable for both standard and bespoke requirements. We offer customization in dimensions, thickness, mounting type, and backing, making them a great fit for unique operational demands. Whether you need bonded or riveted mounting, metal backing, or various sizes, we tailor the product to your precise needs.

Reliable Performance and LongevityConstructed using asbestos fiber with yarn and finished to a woven, textured standard, our brake linings maintain strength and friction over their extended shelf life of up to 5 years. Their resistance to oil and water guarantees stable operation in harsh industrial settings. Complying with IS 11871 & IS 3617 standards, you can rely on these linings for sustained effectiveness and safety.

FAQs of Asbestos Woven Brake Lining:

Q: How do I choose the right thickness and backing for the brake lining?

A: The ideal thickness (3 mm to 25 mm) and backing depend on your machinerys brake load and design. Metal backing is recommended for enhanced stability in heavy-duty applications, while non-backed variants permit greater flexibility. We can assist you in selecting the best option based on your equipments requirements.

Q: What is the maximum operating temperature for this brake lining, and how does it benefit industrial use?

A: The brake lining is designed for continuous use at temperatures up to 350C. This high thermal resistance ensures safe and consistent performance in environments with intense frictional heat, maximizing equipment uptime and reliability.

Q: When should the brake lining be replaced, and what is its shelf life?

A: Brake linings should be inspected regularly for wear. Typically, their shelf life is up to 5 years if stored under recommended conditions, but replacement intervals depend on usage intensity and operating environment. Observing the minimum thickness and monitoring friction performance are key factors for timely replacement.

Q: Where can these asbestos woven brake linings be used?

A: These linings are suitable for a variety of mechanical braking systems, including industrial machinery like cranes, elevators, hoists, winches, lifts, conveyors, brake shoes, and drums. Their oil and water-resistant properties make them particularly valuable in robust industrial settings.

Q: What is the process for ordering customized brake linings?

A: You can request customizations for dimensions, mounting type (bonded or riveted), thickness, size, and backing. Simply share your specific requirements with us, and our team will provide tailored solutions along with lead time and pricing details.

Q: How does the woven fabric design impact the linings performance?

A: The woven fabric construction offers superior flexibility, strength, and heat dissipation, ensuring even wear and stable friction coefficients. This translates to smoother braking, reduced noise, and extended service life during operation.

Q: What are the key benefits of using these linings for industrial applications?

A: Our asbestos woven brake linings deliver high durability, dependable friction, resistance to oil and water, noise reduction, and adaptability for diverse mounting and sizing needs, making them an efficient and long-lasting choice for demanding mechanical braking environments.