About Brake Lining

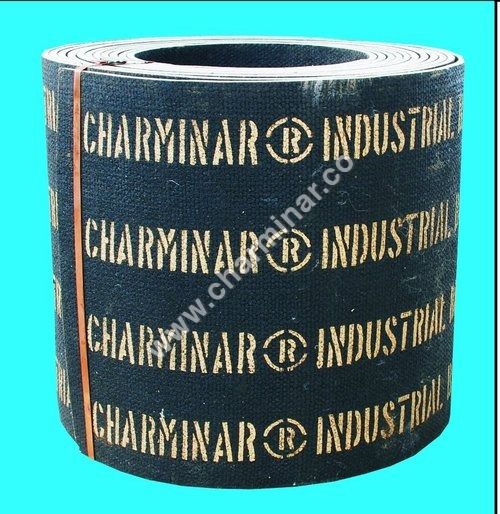

With our best expertise in this domain, we are engaged in offering a wide assortment of Brake Linings. The Brake Liner offered by us is manufactured at our highly advanced manufacturing unit by utilizing the best grade asbestos and asbestos free material with ultra modern technology. It is highly demanded in Shipping, Steel (Steel Melting Shops) Cement , Heavy Equipment manufacturing Indutries, for their EOT cranes. Also used in Lifts, Excavators, Winches, concrete mixers, drop hammers, haulages, tipers road rollers, sugar mill centrifuges etc. Offered lining is available in diverse roll sizes, lengths and thicknesses as per application requirement. In order to gain optimum contentment of clients, we offer this product at pocket friendly prices.

Features:

Durable and Versatile Brake LiningsOur brake linings are crafted to withstand intense pressure and high temperatures, ensuring long-lasting reliability in challenging environments. Available in multiple thicknesses and widths, they accommodate diverse appliances, from heavy machinery to standard vehicles. The roll form enables easy customization and streamlined installation, and the asbestos-free alternative offers a safer option for environmentally conscious users.

Wide Range of ApplicationsThese brake linings are suited for various sectors including automotive, industrial machinery, and heavy transport systems. Their robust compressive strength and stable coefficient of friction deliver consistent braking performance under tough conditions, meeting requirements for exporters, importers, manufacturers, suppliers, and wholesalers in India and abroad.

FAQs of Brake Lining:

Q: How is the brake lining installed, and what makes roll form advantageous?

A: Brake linings in roll form can be easily cut and shaped to fit different braking systems, facilitating flexible installation for vehicles or machinery. This format is preferred for its adaptability and reduces waste during the fitting process.

Q: What is the compressive strength of the brake lining and why is it important?

A: The brake lining exhibits a compressive strength of 900 kg/cm, which ensures it can handle heavy loads and resist deformation. This property is crucial for maintaining safe and efficient braking in demanding applications.

Q: When should I choose asbestos-free (golden) brake linings over asbestos (black) ones?

A: Asbestos-free, golden brake linings are recommended for environments prioritizing health, safety, and eco-friendliness. They deliver comparable performance and help reduce exposure to hazardous materials in the workplace.

Q: Where can these brake linings be sourced and who can purchase them?

A: Our brake linings are manufactured, supplied, and exported from India. Exporters, importers, manufacturers, suppliers, and wholesalers can all order directly, either domestically or internationally.

Q: What is the working temperature range for these brake linings?

A: They can operate reliably at temperatures up to 260C, making them suitable for high-temperature industrial and vehicular braking systems.

Q: How does the coefficient of friction affect the brake linings performance?

A: With a coefficient of friction between 0.3 and 0.4, the lining offers balanced braking efficiency, preventing gear slippage and providing smooth stopping action without wearing out prematurely.

Q: What benefit does the adjustable thickness and width offer the end user?

A: The 5mm to 25mm thickness range and widths up to 510mm ensure compatibility with various brake configurations, making these linings versatile for multiple applications.